Groupe Lactalis is the global leader in cheese and the second largest dairy company worldwide. BasePower developed, installed and now operates a CHP scheme at The Caledonian Cheese Company dairy in Stranraer, Scotland.

The challenge for food manufacturers

Energy intensive industries such as food manufacturing face rapidly rising energy costs, driven by the low pound and sharp increases in power prices. Businesses are also under pressure from retailers to reduce their environmental footprint and to meet their own Climate Change targets. The withdrawal of subsidies for renewable energy projects since 2014 is making it increasingly difficult to meet these challenges without using Combined Heat and Power (CHP).

Groupe Lactalis is the global leader in cheese and the second largest dairy company worldwide. Its Caledonian Cheese Company site in Stranraer, Scotland, manufactures brands including Seriously Strong, McLelland Mature and Galloway, as well as a number of private label brands for leading UK food retailers.

Recognising the uncertainty of investment in UK energy infrastructure combined with increased competition in its supply chain, Lactalis sought an on-site energy generation solution that would lower its energy costs and CO2 emissions, and provide a more sustainable use of energy for the future.

The Lactalis and BasePower energy partnership

The CHP Engine Test

Lactalis and BasePower worked in partnership for over a year to analyse existing uses of energy at the Stranraer site and develop a CHP scheme that would perfectly meet its needs.

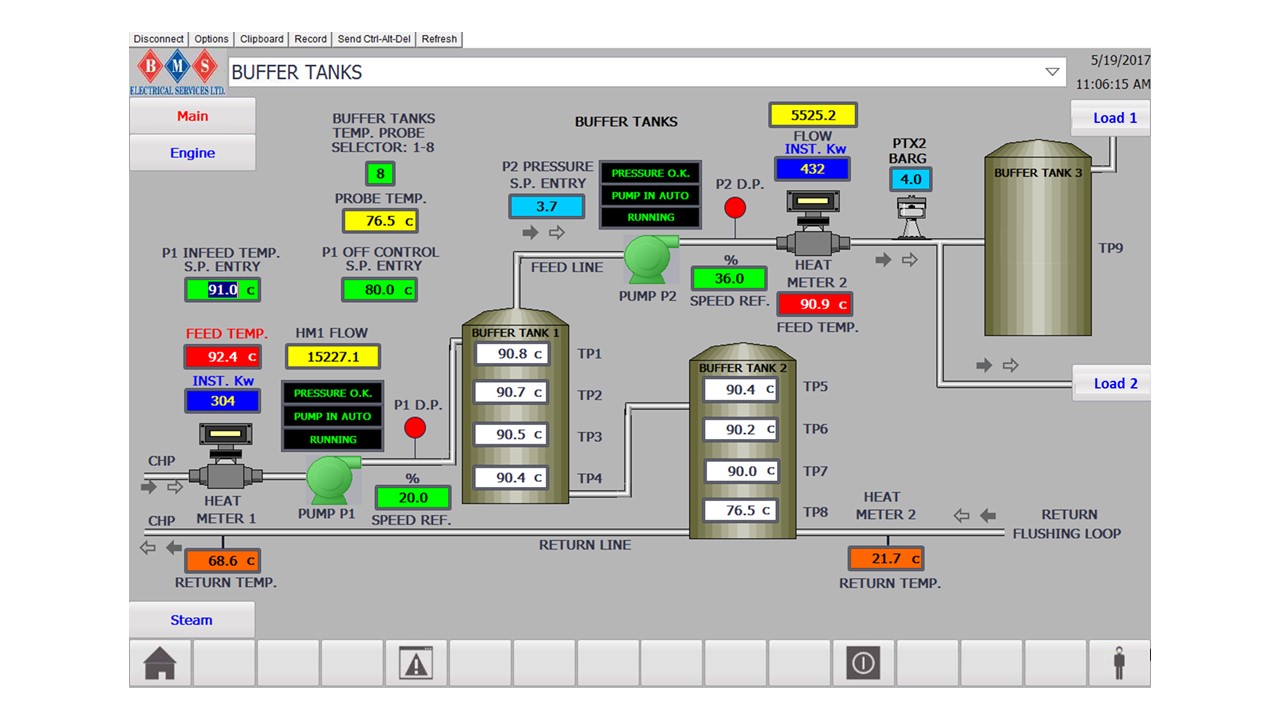

The final project was signed in February 2016 and was financed and installed by BasePower in close collaboration with the Creamery. The CHP project is sized to provide the site’s 2MW power base load, supplying 1MW of steam and a similar quantity of hot water for use around the factory. BasePower operates the CHP project on a day-to-day basis.

The CHP project combines BasePower’s experience in on-site power generation with Lactalis’s expertise in the fine temperature and flow control needed for consistently high quality cheese production. Local contractors were used for much of the construction due to their deep knowledge of the site and its operations.

The CHP project at The Caledonian Cheese Company supplies power, steam and hot water to the dairy.

Operational and strategic benefits

“We were delighted to partner with BasePower on the CHP project which underscores our commitment to keep Lactalis at the forefront of cost competitiveness and environmental performance.”

Mark Taylor, Group Managing Director, Lactalis McLelland

The project was switched on in December 2016. The use of the heat generated by the CHP scheme will significantly reduce the dairy’s grid gas consumption and reliance on the National Grid, and provide a more sustainable use of energy.

The BasePower CHP scheme will reduce the wear and tear on the dairy’s heat-producing assets thereby increasing resilience. In addition, the scheme will be a major driver towards improving the site’s sustainability, reducing emissions by at least 2,000 tonnes of CO2 per year due to improved efficiencies.